Nuxurka nadiifinta laysarka waa cufnaanta tamarta sare ee shucaaca laysarka ee dusha sare ee workpiece, si dusha sare ee wasakhda shaqada, oxidation, dahaarka ama dahaarka, iwm. by kulaylka dhalaalka degdega ah, ablation, uumiga. ama xariijimo, si ay u gaaraan dusha nadiif ah workpiece ah oo aan waxyeello habka substrate ah, waa doorashada ugu fiican ee jiilka cusub ee technology nadiifinta warshadaha.

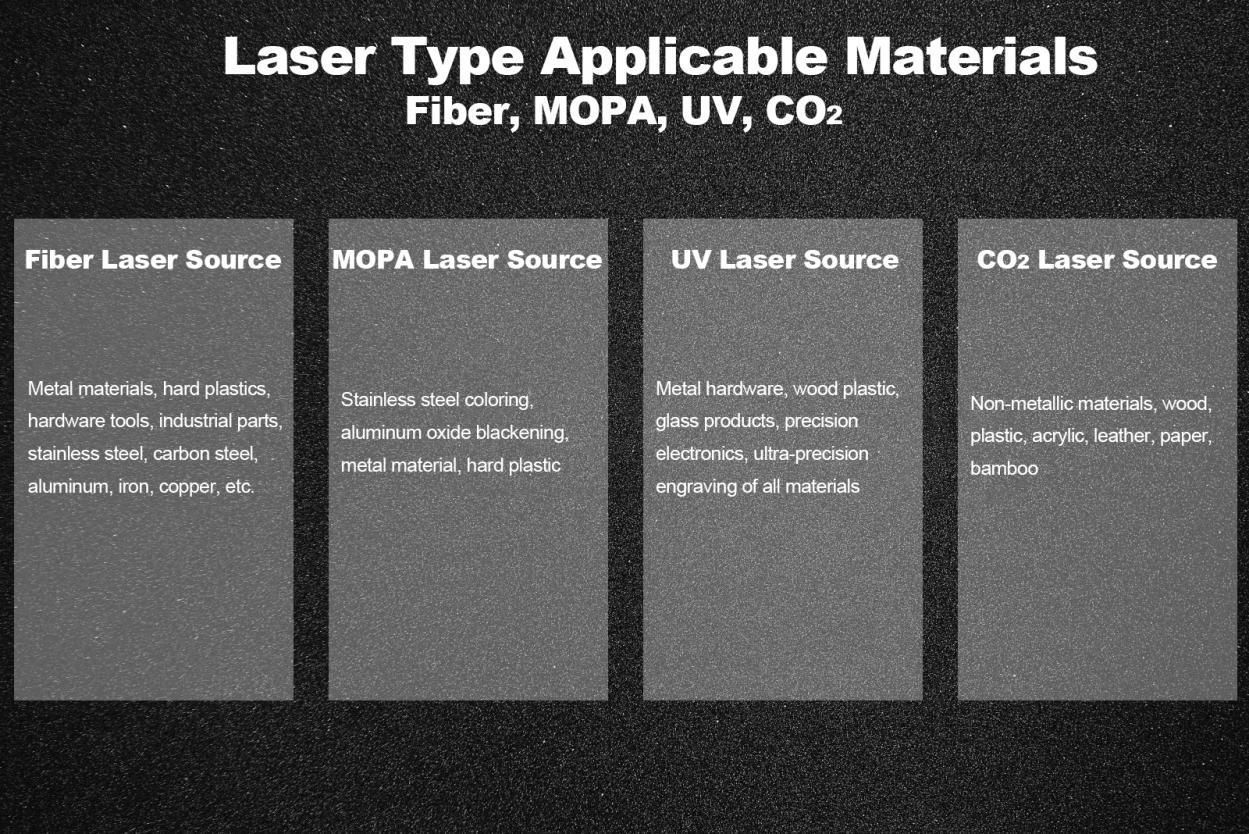

Nooca Laser-ka Qalabka lagu dabaqi karo

Horumarinta Laser isla mar ahaantaana waxay kor u qaadaysaa horumarka degdega ah ee tignoolajiyada nadiifinta laser-ka ee Shiinaha, tignoolajiyada nadiifinta laser-ka ayaa sidoo kale noqotay tignoolajiyada nadiifinta lagama maarmaanka ah ee warshadaha, badda, hawada iyo meelaha kale ee wax soo saarka sare, oo ay ku jiraan ka saarida wasakh caag ah dusha sare ee caaryada taayirrada, ka saarista wasakhda saliidda silikoon ee dusha sare ee filimka dahabka ah iyo nadiifinta saxda ah ee sare ee warshadaha microelectronics.

Ka saarida miridhku dusha birta, ka saarida rinjiga, saarista saliida iyo ka saarida lakabka oksaydhka ayaa ah codsiga ugu badan ee goobta nadiifinta laysarka.Inta u dhaxaysa laysarka kala duwan ee mawjadaha, awoodda iyo xuduudaha kale ee muhiimka ah ee kala duwanaanshaha, qalabka kala duwan, wasakhda dhererka dhererka laser, awoodda iyo shuruudaha kale way ka duwan yihiin, shaqada nadiifinta dhabta ah waxay u baahan tahay in la doorto hababka nadiifinta laysarka ee kala duwan iyadoo loo eegayo xaaladda dhabta ah.

Ka dib markii tiro badan oo tijaabo ah oo xaqiijin ah oo ay sameeyeen kooxda cilmi baarista iyo horumarinta ee MavenLaser, MOPA laser, laser compound waa suuqa ugu isticmaalka badan ee nadiifinta laysarka, oo ay ku xigto tiro yar oo ah codsiyada lasers carbon dioxide, laser ultraviolet, lasers joogto ah.

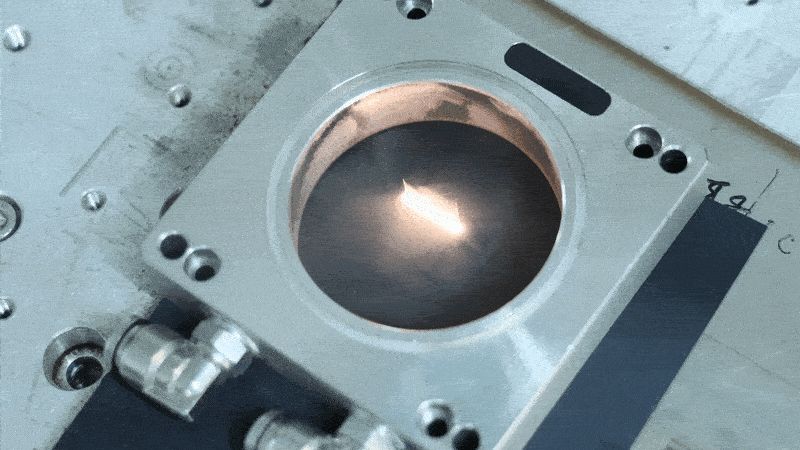

1.MOPA pulsed laser nadiifinta nadiifinta dusha walxaha kala duwan

Godka resonant ee nidaamka laser fiber MOPA laftiisa waa fiber indhaha, iyo MO (Master Oscillator) waa leys awood hoose, kaas oo guud ahaan loo doortay mawjadda ay ku haboon.Laysarka awoodda hooseeya ee LD (laser Diode) wuxuu si toos ah u beddeli karaa cabbirrada wax-soo-saarka iyadoo la raacayo darawalka hadda socda, ka dibna iftiinka calaamada ee ay dhaliso LD wuxuu ku lammaan yahay nidaamka kor-u-qaadista awoodda PA (Power Amplifier) iyadoo loo marayo pigtail si loo kordhiyo iftiinka iftiinka.

Laser MOPA waa nadiifinta laser-ka ugu badan ee la isticmaalo, sababtoo ah nidaamka laser fiber MOPA si adag loo lamaan karaa nidaamka isha signal abuurka ah ee kor u qaadis, ma beddeli doono sifooyinka laser sida mawjada dhexe, waveform garaaca garaaca wadnaha iyo ballaca garaaca wadnaha.Sidaa darteed, cabbirka hagaajinta cabbirku waa mid sarreeya oo ballaadhan, xaaladaha kala duwan ee codsiyada kala duwan ee qalabka kala duwan, la qabsan karo iyo habka daaqada ayaa ka weyn, si loo daboolo nadiifinta dusha sare ee alaabta kala duwan.

Intaa waxaa dheer, laser MOPA leeyahay margin tamar laser sare, waxaa lagu hagaajin karaa by hagaajinta qalabka nadiifinta laser, sida kordhinta booska processing laser, oo leh nidaamyada caqliga leh, iwm, si loo gaaro casriyeynta qalabka nadiifinta laysarka.Waxaa xusid mudan in ay sabab u tahay waxqabadka wanaagsan iyo xaaladaha dabacsan ee ku habboon laser MOPA, waxaa si gaar ah loogu isticmaalaa baytariyada tamarta cusub iyo warshadaha kale ee soo baxaya.

| New Battery Power Tamarta | Nadiifinta tiirka baytariyada Lithium, nadiifinta tiirka tiirka, nadiifinta dekedda duritaanka dareeraha, nadiifinta daboolka, nadiifinta filimka buluuga ah, iwm. |

|

Hawada hawada | Nadiifinta qaybaha matoorka alxanka ka hor iyo ka dib, nadiifinta haanta kaydinta baabuurka alxanka ka hor iyo ka dib, ka saarida rinjiga alaabta isku dhafan, saarista wakiilka sii daynta, saarista maqaarka diyaarada, saarista shaambada, nadiifinta caaryada |

| Alaabta caaryada | Caaryada taayirka, caaryada daboolka, caaryada duritaanka, caaryada xidhitaanka, caaryada cuntada, iwm. si looga saaro lakabka kaarboonka |

| 3C Warshadaha | Xulashada guddiga wareegga iyo saarista rinjiga, nadiifinta waferka, ka saarista rinjiga taleefanka gacanta, nadiifinta dahaarka PVD |

| Wax-soo-saarka baabuurta | Nadiifinta hore ee jirka, nadiifinta taayirrada, ka saarida rinjiga meelaha la doortay ee jirka, taayirada aamusan |

| Maraakiibta badda | Nadiifinta alxanka ka hor iyo ka dib alxanka, ka saarista rinjiga qaybo ka mid ah, nadiifinta saliidda |

| Buundada, dayactirka wadada weyn | Qaybaha qaab dhismeedka buundada rinjiga ka saarida, saarista miridhku, saarista rinjiga wadiiqada |

| Gaadiidka tareenka | Nadiifinta jirka aluminium ka hor iyo ka dib alxanka, lamaanayaasha taayirrada nadiifinta tooska ah, nadiifinta bogie, nadiifinta mootada, iwm. |

| Kiimikada batroolka | Ka saarida dahaadhka saliidda ee xeebaha, saarista rinjiga tuubada, saarista miridhku, iwm. |

| Warshadaha cuntada | Digsiyada birta lagu dubayo, caaryada, iwm. |

| Koob vacuum | Ka saarida rinjiga gunta iyo gidaarka koobabka dahaarka leh |

| Warshadaha kale | Saliidda saliidda birta, nadiifinta tuubada shaandhada, nadiifinta birta aan-lahayn, saarista miridhku leysarka, saarista oksaydhka |

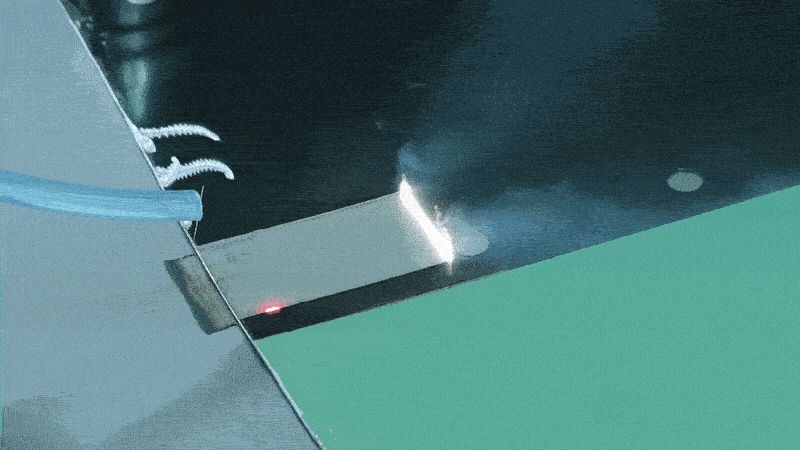

2.Nadiifinta laysarka isku dhafan, doorashada ugu fiican ee rinjiga saarista

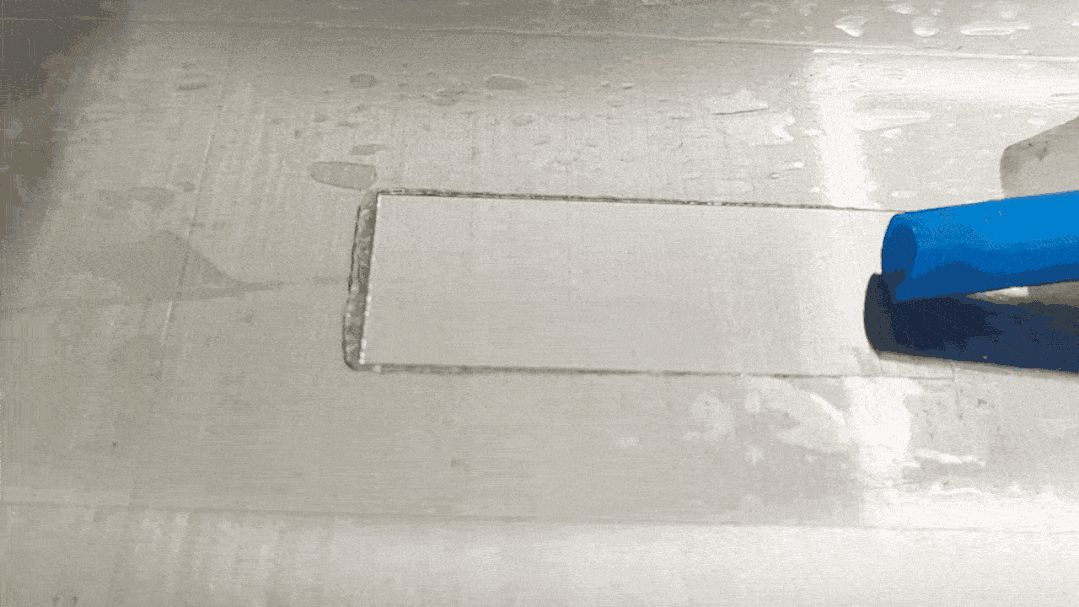

Nadiifinta isku-dhafka Laser-ka iyada oo loo marayo semiconductor laser joogto ah sida wax soo saarka kulaylka, si xabagta la nadiifiyo ay u nuugaan tamarta si ay u soo saaraan uumiga, daruuraha plasma, iyo samaynta cadaadiska fidinta kulaylka ee u dhexeeya walxaha birta iyo xabagta, hoos u dhigista xoogga isku xirnaanta ee u dhexeeya labada lakab.Marka laysarka uu soo saaro tamar sare oo garaaca laysarka garaaca wadnaha, ka dhalanaya ruxruxo ruxruxo mawjada si aanay curaarta ma aha koollo xoog leh si toos ah oogada birta, si loo gaaro nadiifinta laser degdeg ah.

Ka saarida rinjiga qolofka unugyada xoogga ah

Nadiifinta isku-dhafan ee leysarka iyadoo leys joogto ah iyo isku-dhafka shaqeynta garaaca wadnaha, sameynta sifooyin wax-qabad oo 1 + 1>2 ah.Xawaaraha degdega ah, wax ku oolnimada sare, tayada nadiifinta lebbiska oo dheeraad ah, qalabyo kala duwan, waxaad sidoo kale isticmaali kartaa mawjadaha dhererka kala duwan ee nadiifinta laysarka isku mar si loo gaaro ujeedada ka saarista wasakhda.

Rinjiga ka saarista matoorada timaha

Waqtigan xaadirka ah, nadiifinta isku dhafka laysarka waxaa si weyn loogu isticmaalaa maraakiibta, dayactirka baabuurta, caagadaha caagga ah, qalabka mashiinka-dhamaadka sare, tareenka iyo ilaalinta deegaanka iyo beeraha kale, si wax ku ool ah u saar shayga dusha sare, rinjiga, saliidda, wasakhda, wasakhda, miridhku, dahaarka , dahaarka iyo lakabka oksaydhka.

Tusaale ahaan, in daahan ka dhumuc weyn yahay wax soo saarka laser, hal laser multi-pulse tamarta wax soo saarka, kharashka sare, isticmaalka laser pulsed - semiconductor laser nadiifinta isku dhafan, si degdeg ah oo wax ku ool ah u hagaajin kartaa tayada nadiifinta, oo aan waxyeello substrate-ka;ee daawaha aluminium iyo qalab kale oo aad u milicsiga laser nadiifinta, hal laser milicsiga iyo dhibaatooyin kale.Isticmaalka laser pulsed - nadiifinta isku dhafka laser semiconductor, doorka wareejinta kuleylka laser semiconductor, kordhinta heerka nuugista tamarta lakabka oxide dusha birta, si iftiinka laser garaaca wadnaha uu u dhaqso badan yahay inuu ka saaro lakabka oksaydhka, sidaas darteed si wax ku ool ah loo hagaajiyo waxtarka saarista, gaar ahaan marka lagu daro waxtarka rinjiga oo kordhay in ka badan 2 jeer.

3.Kaarboon dioxide nadiifinta laser, doorashada ugu fiican ee ka saarida alaabta aan biraha ahayn

CO2 lasers waa laser gaas oo leh CO2 gaaska sida walaxda shaqada, oo ay ka buuxaan gaaska CO2 iyo gaasaska kale ee caawiya (helium iyo nitrogen iyo qadar yar oo hydrogen ama xenon ah), kuwaas oo leh jihada wanaagsan, monochromaticity iyo xasilloonida soo noqnoqda.Maadaama tuubada dheecaanku ka samaysan tahay dhalo ama walxo quartz ah, laba nooc oo caadi ah oo CO2 lasers ah waa tuubada dhalada CO2 lasers iyo birta RF tube CO2 lasers.

Ciridka ka saarida

4.UV laser nadiifinta qalabka saxda ah

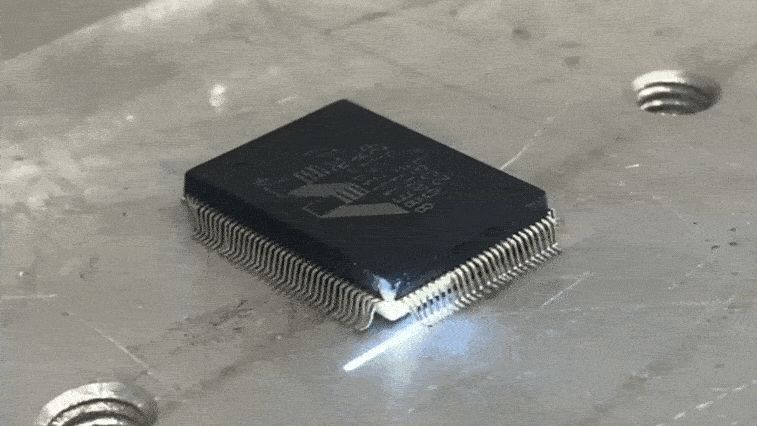

Laysarka UV-ga ugu weyn ee loo isticmaalo microfabrication laser waa lasers excimer iyo lasers-state oo dhan.Laser UV oo leh hirar gaaban iyo tamar sare oo hal sawir ah ayaa si toos ah u jebin karta curaarta kiimikada ah ee ku xiran walxaha, iyo walxaha waxaa laga xayuubiyay dusha sare ee qaab gaas ama qaybo, iyo aagga kuleylku saameeyay ee ka soo baxa inta lagu jiro farsamaynta ayaa yar, kaas oo leh faa'iidooyinka gaarka ah ee microfabrication, sida Si, GaN iyo walxaha kale ee semiconductor, quartz, sapphire iyo kiristaalo kale oo indhaha ah, iyo polyimide (PI), polycarbonate (PC) iyo qalabka kale ee polymer, oo si wax ku ool ah u hagaajin kara tayada wax soo saarka.

Nadiifinta biinka jajabka

Laser UV waxaa loo arkaa inuu yahay xalka ugu fiican ee nadiifinta laser berrinkii elektiroonigga saxda ah, ay ugu sifo wanaagsan technology processing "qabow" ma beddelo sifooyinka jireed ee shayga isku mar, dusha micro-processing iyo processing, karaa in si weyn loogu isticmaalo warshadaha iyo qaybaha kala duwan sida isgaarsiinta, indhaha, ciidamada, dambi baarista, caafimaadka.Tusaale ahaan, waagii 5G waxa uu abuuray baahida suuqa ee habaynta FPC.Codsiga mashiinka laysarka UV wuxuu suurtogal ka dhigayaa saxnaanta qabow ee FPC iyo agabyada kale.

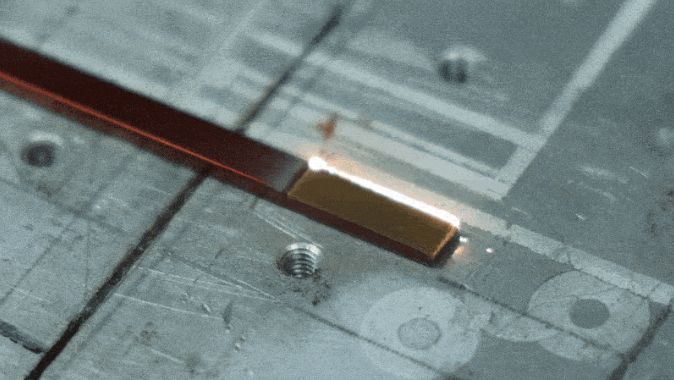

5.Nadiifinta laser fiber-ka joogtada ah si looga saaro miridhku sabayn ee sagxadaha birta ah

Laser-ka fiber-ka joogtada ah wuxuu u shaqeeyaa isagoo iftiinka ka soo shubaya isha matoorka iyada oo loo marayo muraayad lagu dhejiyo dhexdhexaadka faa'iidada, sababtoo ah dhexdhexaadinta faa'iidada waa element naadir ah oo fiber ah, sidaas darteed iftiinka bamka ayaa nuugaya, tamarta photon ee la nuugo heerka tamarta dhifka ah ee dhulka iyo gaadhaan rogrogis tirada qayb ka dib, ka dib roganta qayb ka dhex godka resonant, ka gobolka ku faraxsan boodaan dib u gobolka dhulka, sii daayo tamarta, oo ay sameeyaan wax soo saarka laser xasiloon, faa'iidada ugu weyni waa in iftiinku noqon karaa joogto ah.

Nadiifinta alxanka ka dibC

Codsiyada nadiifinta laser-ka dhabta ah, codsiga laser fiber joogtada ah waa ka yar yahay, laakiin waxaa jira tiro yar oo codsiyo ah, sida qaar ka mid ah dhismayaasha birta ee waaweyn, dhuumaha, iwm. sare, ka dibna waxaad dooran kartaa laser joogto ah.

Ka saarida miridhku

Waxaa xusid mudan in horumarka iyo xasiloonida tignoolajiyada booska giraanta, laser fiber giraanta leh faa'iidooyinka habaynta habka fudud iyo hawlgalka fudud ayaa si weyn loogu caan baxay beerta alxanka iyo nadiifinta, ka dib tiro badan oo tijaabo ah injineerada Xarunta Habka MavenLaser, tignoolajiyada waxaa loo isticmaalaa in meesha laga saaro miridhku sabaynaya, kaas oo si weyn u hagaajin kara waxtarka nadiifinta.

Iyada oo horumarka sayniska iyo tignoolajiyada iyo hagaajinta shuruudaha ilaalinta deegaanka, nadiifinta laser-ka ayaa si qoto dheer oo dhamaystiran uga qayb qaadan doona habka soo-saarka warshadaha Shiinaha, oo noqda habka ugu muhiimsan ee nadiifinta wax soo saarka nadiifka ah ee warshadaha.

Shenzhen Maven Laser Automation Co., Ltd., oo xarunteedu tahay Shenzhen, waxay leedahay warshad wax soo saar u gaar ah.Diirada saarista duurka codsiyada farsamada sare ee laser, iyadoo la raadinayo wax soo saarka sida ujeedada aasaasiga ah, si loo siiyo macaamiisha goynta laser, alxanka laysarka, calaamadaynta laser, nadiifinta laysarka, korontada laserka oo buuxa adeegyo xal-ku-salaysan, sida laga soo xigtay baahida macaamiisha, horumarinta barnaamijka nadiifinta tooska ah si loo gaaro ujeedooyin nadiifin oo caqli badan.In berrinkii mashiinka nadiifinta laysarka waa booska hogaaminaya, alaabta ay ka mid ah nooca golaha wasiirada mashiinka nadiifinta laser, jiid ul nooca laser nadiifinta mashiinka, mashiinka nadiifinta nooca garabka dhabarka noocyo kala duwan oo isticmaalka mashiinka nadiifinta laser model.Nidaamka suuq-geynta wax soo saarka ee saxda ah iyo nidaamka adeegga iibka kadib si alaabtu uga dhigto mid tartan badan, 24 saacadood wakhti kasta si ay uga jawaabto inay ku siiso silsilad alaabooyin ah adeegyada dayactirka iibka ka dib.Tiknoolajiyada MavenLaser waxay kugu cajabin doontaa tayada tignoolajiyada xasilloon, qiimaha macquulka ah ee adeegga, oo waxay noqon doontaa lammaanahaaga daacadda ah!

Waqtiga boostada: Jan-16-2023