Sanadihii la soo dhaafay, nadiifinta laser waxay noqotay mid ka mid ah goobaha cilmi-baarista ee berrinkii wax soo saarka warshadaha, cilmi-baaristu waxay dabooshaa habka, aragtida, qalabka iyo codsiyada. Codsiyada warshadaha, tignoolajiyada nadiifinta laysarka ayaa awooday inay si kalsooni leh u nadiifiso tiro badan oo dusha sare ah oo kala duwan, walxaha nadiifinta oo ay ku jiraan birta, aluminium, titanium, dhalooyinka iyo walxaha isku dhafan, iwm., warshadaha codsiga ee daboolaya hawada, duulista, dhoofinta, xawaaraha sare tareenka, baabuurta, caaryada, tamarta nukliyeerka iyo badda iyo beeraha kale.

Tiknoolajiyada nadiifinta leysarka, oo soo bilaabatay 1960-meeyadii, waxay leedahay faa'iidooyinka nadiifinta wanaagsan, codsiyo kala duwan, saxsanaan sare, xiriir la'aan iyo helitaan. In wax soo saarka warshadaha, wax soo saarka iyo dayactirka iyo beeraha kale waxay leeyihiin tiro balaadhan oo ah fursadaha codsiga, waxaa la filayaa in qayb ahaan ama gebi ahaanba beddelo hababka nadiifinta dhaqanka, oo ay noqdaan technology nadiifinta cagaaran ugu rajo qarniga 21aad.

Habka nadiifinta laser

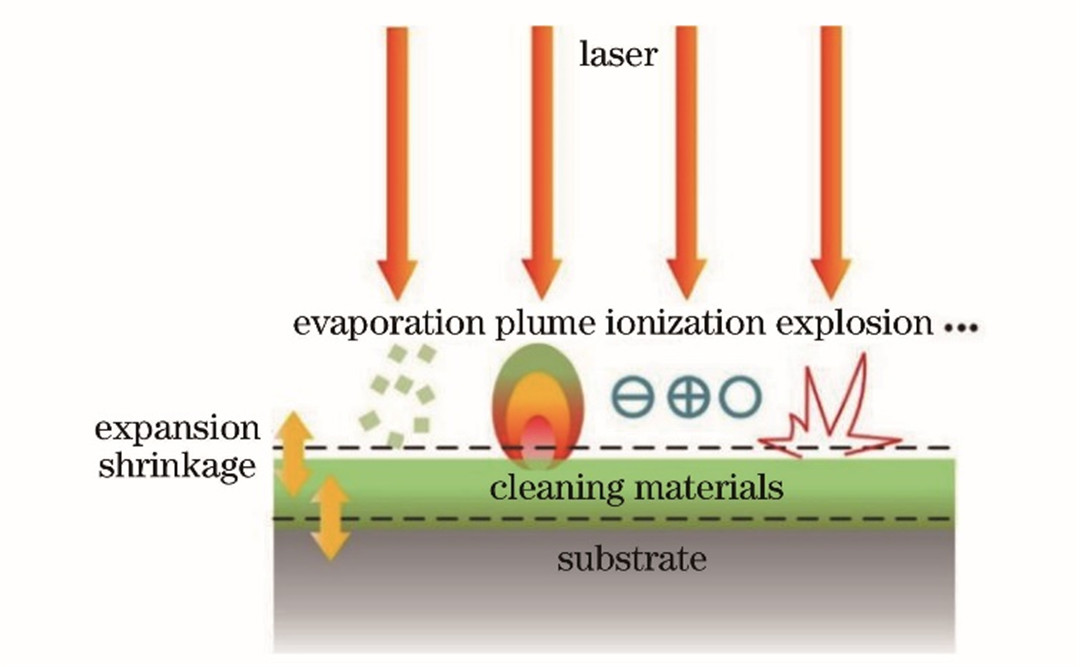

Habka nadiifinta Laser waa mid aad u adag, oo ku lug leh noocyo kala duwan oo ka mid ah hababka saarista walxaha, habka nadiifinta laysarka, habka nadiifinta ayaa laga yaabaa inuu jiro waqti isku mid ah habab kala duwan, taas oo inta badan loo aaneeyo isdhexgalka ka dhexeeya laysarka iyo walxaha, oo ay ku jiraan nuugista maaddada oogada, kala-goynta, ionization, xaalufka, dhalaalka, gubashada, uumiga, gariirka, sputtering, ballaarinta, yaraanshaha, qaraxa, diirka, daadinta iyo isbeddellada kale ee jirka iyo kiimikada. habka.

Waqtigan xaadirka ah, hababka nadiifinta laysarka ee caadiga ah waxay u badan yihiin saddex: nadiifinta laysarka nadiifinta, nadiifinta laysarka ee dareeraha ah ee lagu caawiyo iyo hababka nadiifinta hirarka shoogga laysarka.

Habka nadiifinta nabarrada laser-ka

Hababka ugu muhiimsan ee dariiqooyinka waa balaadhinta kulaylka, uumiga, ablation iyo qaraxa wajiga. Laysarku wuxuu si toos ah ugu shaqeeyaa shayga laga saarayo dusha sare ee substrate-ka iyo xaaladaha deegaanku waxay noqon karaan hawo, gaas naadir ah ama faakuum. Xaaladaha qalliinka waa sahlan yihiin oo inta badan loo isticmaalo in laga saaro noocyo kala duwan oo dahaar ah, rinji, qaybo ama wasakh. Jaantuska hoose wuxuu muujinayaa jaantuska habka habka nadiifinta ablation-ka laysarka.

Marka shucaaca laysarka ee dusha sare ee walxaha, substrate-ka iyo alaabta nadiifinta ayaa ah balaarinta kulaylka ugu horreeya. Kordhinta wakhtiga isdhexgalka laysarka ee alaabta nadiifinta, haddii heerkulku uu ka hooseeyo heerka nadiifinta walxaha nadiifinta, walxaha nadiifinta ee habka isbeddelka jirka oo kaliya, farqiga u dhexeeya walxaha nadiifinta iyo isugeynta fidinta kuleylka substrate waxay keenaysaa cadaadis at interface. , Qalabka nadiifinta ee ku dhufan, jeexjeexa dusha sare ee substrate-ka, dillaaca, jabka farsamada, burburinta gariirka, iwm.

Haddii heerkulku ka sarreeyo heerkulka marinka gaaska ee walxaha nadiifinta, waxaa jiri doona laba xaaladood: 1) xadka xad-dhaafka ah ee walxaha nadiifinta ayaa ka yar substrate-ka; 2) xadka ablation ee alaabta nadiifinta ayaa ka weyn substrate-ka.

Labadan xaaladood ee alaabta nadiifinta waa dhalaalid, cavitation iyo ablation iyo isbeddelada kale ee kiimikaad, habka nadiifinta ayaa aad u adag, marka lagu daro saamaynta kulaylka, laakiin sidoo kale waxaa ku jiri kara alaabta nadiifinta iyo substrates inta u dhaxaysa jebinta curaarta molecular, alaabta nadiifinta burburka ama hoos u dhaca, wajiga qaraxa, alaabta nadiifinta gaasification ionization degdeg ah, abuuritaanka balaasmaha.

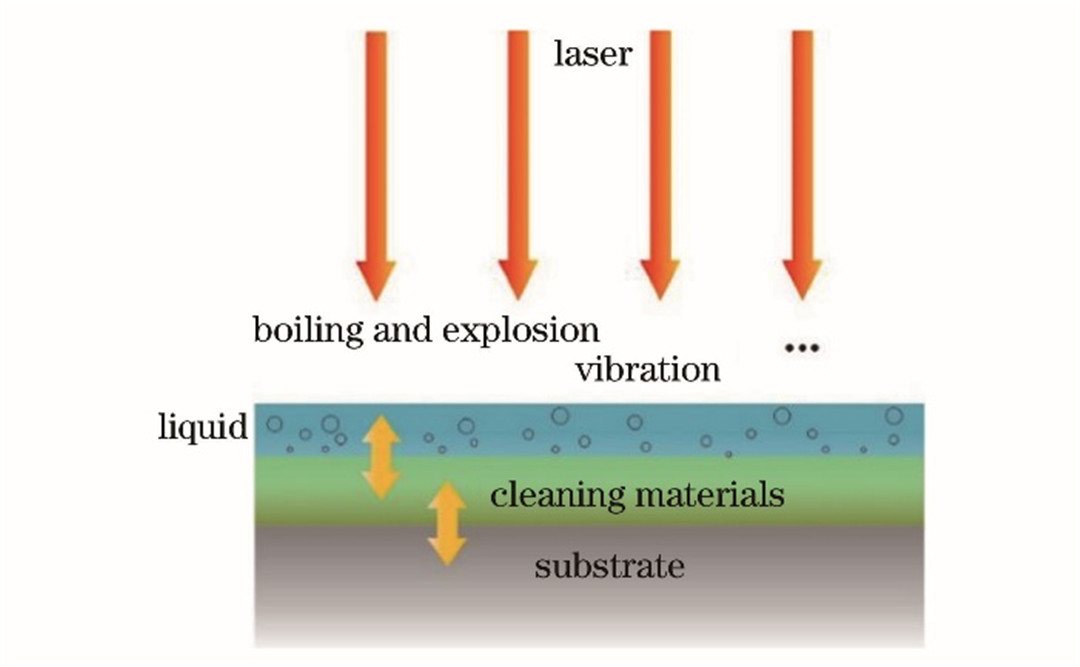

(1)Filimka dareeraha ah ayaa caawiyay nadiifinta laysarka

Habka habka inta badan waxa uu leeyahay film dareere karkaraya uumiga iyo gariirka, iwm .. Isticmaalka baahida loo qabo in la doorto mawjada laser ku habboon, si ay u sameeyaan ilaa la'aanta ah ee cadaadiska saamaynta ee habka nadiifinta ablation laser, waxaa loo isticmaali karaa in meesha laga saaro. qaar ka mid ah kuwa aadka u adag in la saaro shayga nadiifinta.

Sida ku cad sawirka hoose, filimka dareeraha ah (biyaha, ethanol ama dareeraha kale) ayaa horay loogu daboolay dusha shayga nadiifinta, ka dibna isticmaal laser si aad u iftiimiso. Filimka dareeraha ah wuxuu nuugaa tamarta laysarka taasoo keentay qarax xooggan oo ah warbaahinta dareeraha ah, qarxinta dareeraha karkarinta dhaqdhaqaaqa xawaaraha sare, wareejinta tamarta ee alaabta nadiifinta dusha sare, xoogga qarxa ee ku-meel-gaarka ah ayaa ku filan in laga saaro wasakhda dusha sare si loo gaaro ujeedooyinka nadiifinta.

Habka nadiifinta laysarka ee filimka dareeraha ah ayaa leh laba faa'iido darro.

Nidaam dhib badan oo adag in la xakameeyo habka.

Sababtoo ah isticmaalka filimka dareeraha ah, ka kooban kiimiko ee dusha sare ee substrate ka dib nadiifinta waa sahlan tahay in la beddelo oo la abuuro walxo cusub.

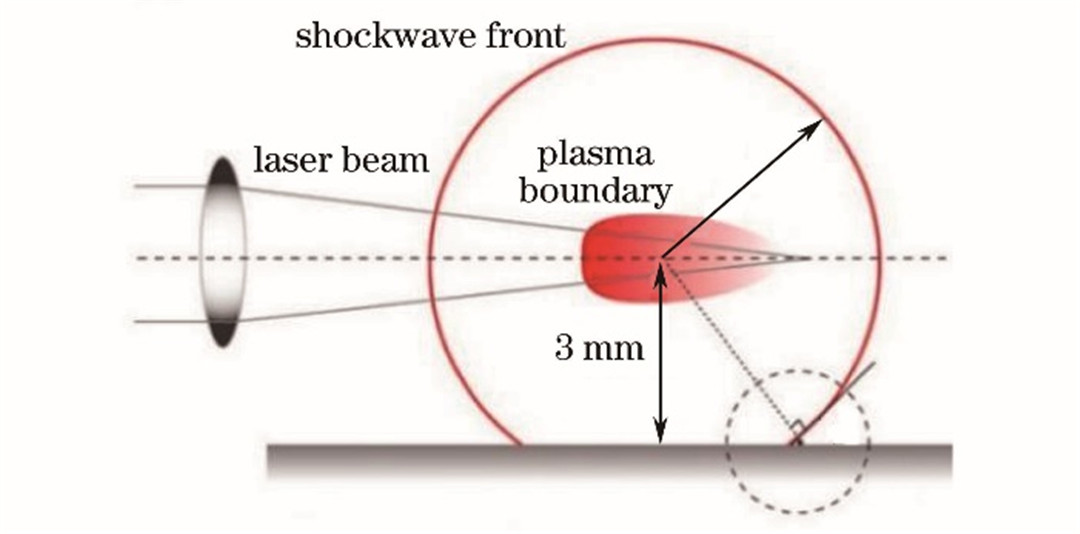

(1)Habka nadiifinta nooca shoogga laser

Habka iyo habka geedi socodka aad ayuu uga duwan yahay labada hore, farsamadu inta badan waa shoogga mawjada ka saarida, walxaha nadiifinta inta badan waa qayb ka mid ah, inta badan ee ka saarida walxaha (sub-micron ama nanoscale). Shuruudaha geeddi-socodku waa kuwo aad u adag, labadaba si loo hubiyo in awoodda ionize hawada, laakiin sidoo kale in la ilaaliyo fogaanta ku habboon ee u dhexeeya laser iyo substrate si loo hubiyo in ficilka qaybaha xoogga saameyntu ay ku filan tahay.

Habka nadiifinta mawjada shoogga leysarka jaantuska jaantuska ayaa hoos lagu muujiyey, laysarka oo barbar socda jihada tallaalka dusha sare ee substrate-ka, iyo substrate-ku ma soo galo. Dhaqaaq qaybta shaqada ama madaxa laser si aad u hagaajiso diiradda leysarka qaybta u dhow wax soo saarka laysarka, barta xudunta u ah ifafaalaha ionization hawada ayaa dhici doona, taasoo keentay mowjado shoog ah, hirarka naxdinta leh si ay u ballaariyaan degdegga ah ee ballaarinta wareega, oo la kordhiyo si loola xiriiro. oo leh qaybaha. Marka la joogo qaybta transverse ee hirarka shoogga on qayb ka weyn yahay la joogo ee qaybta dheer iyo xoogga adhesion qayb, qayb ka saari doonaa by giringiriyey.

Tiknoolajiyada nadiifinta laser

Habka nadiifinta Laser inta badan waxay ku salaysan tahay dusha shayga ka dib nuugista tamarta laysarka, ama uumiga iyo isbeddelka, ama balaadhinta kulaylka degdega ah si looga adkaado xayeysiinta qaybaha dusha sare, si shayga ka soo baxa dusha sare, ka dibna uu gaaro ujeedada nadiifinta.

Qiyaastii waxa lagu soo koobay: 1. Burburka uumiga laysarka, 2. xariijimaha laysarka, 3. balaadhinta kulaylka ee walxaha wasakhda ah, 4. gariirka dusha sare ee substrate iyo gariirka qaybta afar dhinac

Marka la barbardhigo habka nadiifinta dhaqameed, tiknoolajiyada nadiifinta laysarka waxay leedahay sifooyinka soo socda.

1. Waa nadiifin "qalalan", oo aan lahayn xal nadiifin ah ama xalal kiimiko ah oo kale, nadaafadda ayaa aad uga sareysa habka nadiifinta kiimikada.

2. Baaxadda ka saarista wasakhda iyo qiyaasta substrate-ka lagu dabaqi karo waa mid aad u ballaaran, iyo

3. Iyada oo loo marayo nidaaminta xuduudaha habka laser, ma dhaawici karto dusha sare ee substrate ku salaysan ka saarista wax ku oolka ah ee wasakhaysan, waa dusha sare sida cusub.

4. Nadiifinta laser-ku waxay si fudud u noqon kartaa hawl otomaatig ah.

5. Qalabka wasakhaynta laser-ka waxaa loo isticmaali karaa waqti dheer, kharashyada hawlgalka oo hooseeya.

6. Tiknoolajiyada nadiifinta laser waa: cagaar: habka nadiifinta, baabi'inta qashinka waa budo adag, cabbir yar, sahlan in la kaydiyo, asal ahaan ma wasakhayn doonto deegaanka.

Sannadihii 1980-meeyadii, horumarinta degdegga ah ee warshadaha semiconductor ee dusha sare ee qaybaha wasakheynta maaskarada silikoon ee tignoolajiyada nadiifinta ayaa soo bandhigay shuruudo sare, qodobka ugu muhiimsan waa in laga gudbo faddaraynta walxaha yaryar iyo substrate u dhexeeya xoogga weyn ee adsorption , Nadiifinta kiimikada dhaqameed, nadiifinta farsamada, hababka nadiifinta ultrasonic ma awoodaan inay daboolaan baahida, iyo nadiifinta laysarka ayaa xallin kara dhibaatooyinka wasakhaysan, cilmi-baarista iyo codsiyada la xidhiidha ayaa si degdeg ah loo sameeyay.

Sannadkii 1987, muuqaalka ugu horreeya ee codsiga patent-ka ee nadiifinta laysarka. Sanadihii 1990-meeyadii, Zapka waxay si guul leh u adeegsatay tignoolajiyada nadiifinta laysarka ee habka wax soo saarka semiconductor si looga saaro walxaha yar-yar ee dusha sare ee maaskarada, iyada oo garatay codsigii hore ee tignoolajiyada nadiifinta laysarka ee warshadaha. 1995, cilmi-baarayaashu waxay isticmaaleen 2 kW TEA-CO2 laser si ay si guul leh u gaaraan nadiifinta rinjiga fuushanka diyaaradda.

Ka dib markii la soo galo qarniga 21aad, iyada oo horumarinta xawaaraha sare ee laser garaaca garaaca ultra-gaaban, cilmi-baarista gudaha iyo dibadda iyo codsiga tignoolajiyada nadiifinta laser si tartiib tartiib ah u kordhay, diiradda on dusha qalabka biraha, codsiyada shisheeye caadiga ah waa ka saarista rinjiga fuselage diyaaradaha, caaryada. Goynta dusha sare, mishiinka ka saarida kaarboonka gudaha iyo nadiifinta dusha sare ee kala-goysyada ka hor alxanka. US Edison Welding Institute laser nadiifinta diyaaradda dagaalka FG16, marka awoodda laser ee 1 kW, mugga nadiifinta 2.36 cm3 daqiiqadii.

Waxaa xusid mudan in cilmi-baarista iyo adeegsiga rinjiga laysarka ka saarista qaybaha hore ee isku-dhafka ah ay sidoo kale tahay meel kulul oo weyn. Ciidamada badda ee Maraykanka HG53, garbaha helicopter HG56 iyo F16 dabada fidsan jet iyo sagxadaha kale ee isku dhafan ayaa la xaqiiqsaday codsiyada saarista rinjiga laser, halka qalabka Shiinaha ee isku dhafan ee codsiyada diyaarad soo daahay, sidaas cilmi-baarista noocan oo kale ah asal ahaan waa bannaan.

Intaa waxaa dheer, isticmaalka tignoolajiyada nadiifinta laysarka ee CFRP daaweynta dusha isku dhafan ee wadajirka ka hor inta aan la isku dhejin si loo hagaajiyo xoogga wadajirka ayaa sidoo kale ah mid ka mid ah diiradda cilmi-baarista hadda. la qabsiga shirkadda laysarka ee khadka wax soo saarka baabuurta ee Audi TT si ay u bixiso qalabka nadiifinta fiber laser si loo nadiifiyo dusha sare ee aluminium aluminium alwaax khafiif ah filimka oxide. Rolls G Royce UK waxay isticmaashay nadiifinta laysarka si ay u nadiifiso filimka oksaydhka dusha sare ee qaybaha aero-engine-ka titanium.

Tiknoolajiyada nadiifinta laser-ka ayaa si degdeg ah u horumarisay labadii sano ee la soo dhaafay, haddii ay tahay cabbirada habka nadiifinta laysarka iyo habka nadiifinta, nadiifinta shay-baarista ama codsiga cilmi-baarista ayaa sameeyay horumar weyn. Tiknoolajiyada nadiifinta laser ka dib cilmi-baaris badan oo aragti ah, diiradda cilmi-baaristeeda ayaa si joogto ah u xaglinaysa codsiga cilmi-baarista, iyo codsiga natiijooyinka rajo-gelinta ah. Mustaqbalka, tignoolajiyada nadiifinta laysarka ee ilaalinta alaabada dhaqanka iyo farshaxanka ayaa si aad ah loo isticmaali doonaa, suuqgeeduna waa mid aad u ballaaran. Iyadoo horumarinta sayniska iyo tignoolajiyada, codsiga tignoolajiyada nadiifinta laysarka ee warshadaha ayaa noqonaysa mid dhab ah, iyo baaxadda codsigu waxay noqonaysaa mid aad iyo aad u ballaadhan.

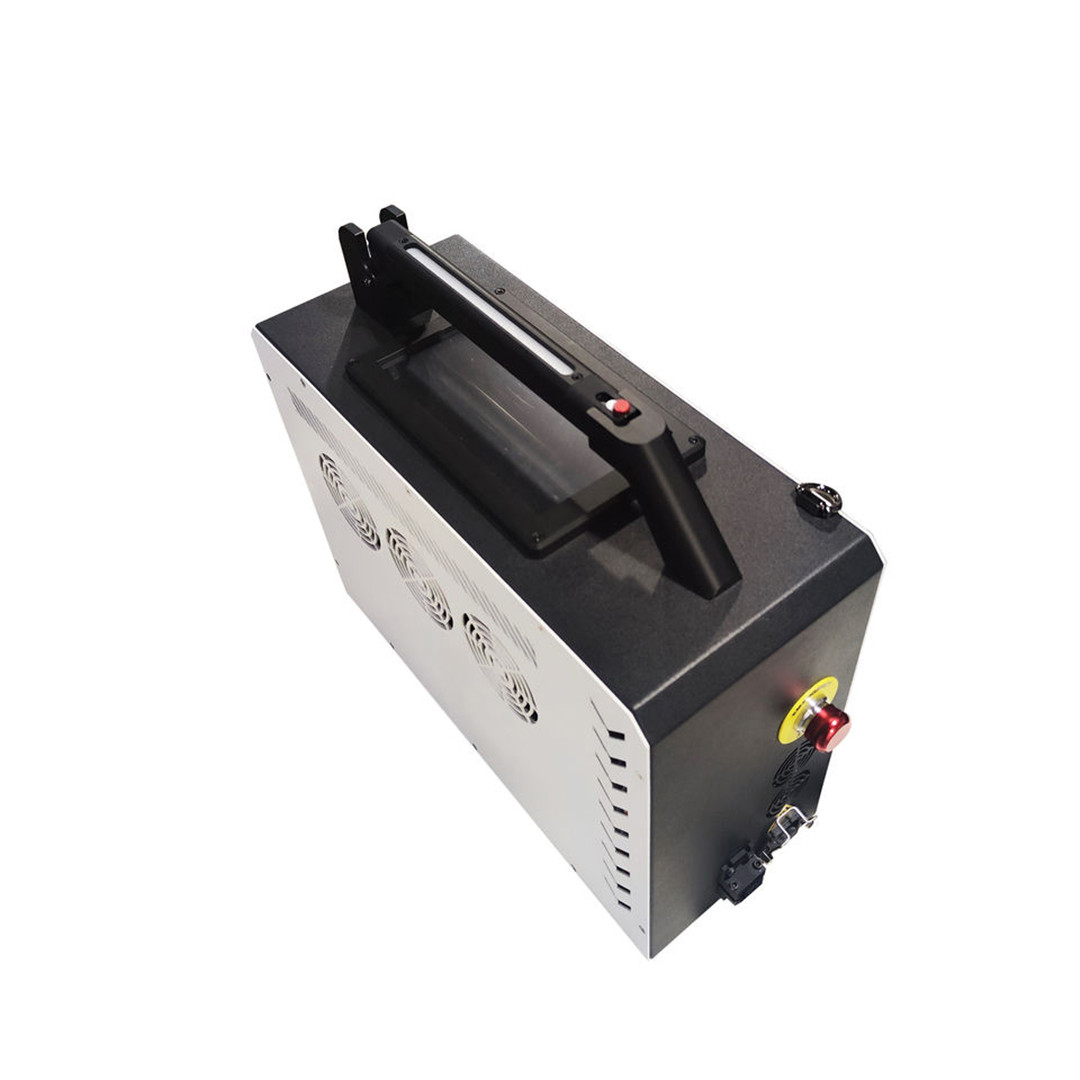

Shirkadda Maven laser automation waxay diiradda saartaa warshadaha laysarka muddo 14 sano ah, waxaan ku takhasusnay calaamadeynta laser, waxaan haynaa mashiinka mashiinka nadiifinta mashiinka nadiifinta laser, mashiinka nadiifinta trolley case laser, mashiinka nadiifinta shandad dhabarka iyo seddex ka mid ah mashiinka nadiifinta laser, marka lagu daro, waxaan sidoo kale haysanaa Mashiinka alxanka laysarka, mashiinka goynta laysarka iyo mashiinka xargaha xargaha laysarka, haddii aad xiisaynayso mashiinkayaga, waad na raaci kartaa oo aad xor u tahay inaad nala soo xidhiidho.

Waqtiga boostada: Nov-14-2022